talbrossealing

Add: Plot No. 60, Sector 6, Faridabad, Haryana – 121006

Phone: 0129-4067000 ; Email: materials@bnt-talbros.com

Website: https://www.talbrossealing.com/

All You Need to Know About The Selection of Friction Material

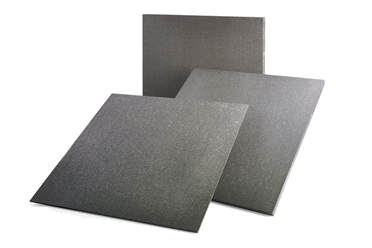

Friction materials are generally used for generating controlled friction for braking or power transfer application while minimizing wear. Cork Friction Material include brake pads, brake shoes, clutch plates, bonded assemblies, friction brands, liners and rolls. During selection of friction materials, the industrial buyers are needed to consider the form and material type along with product and performance specifications.

Friction material forms:

Friction bands are used in automotive transmission and in friction sawing, metal cutting techniques where the blades run at very high speed. Longer saw blades can better dissipate heat where the friction brands are used mainly with very large saws. These are available to any type of Cork Friction Material Manufacturer.

Friction blocks are basically used in overhead cranes, hoists and winches, cranes and shovel bands and mining and oilfield equipment. In that case, some products can be rigid.

Friction pads and shoes are generally used in automotive brakes and braking systems. Friction is used in brake pads for converting the kinetic energy of the car to thermal energy. The friction against the rotor help to provide most of the stopping power.

Friction plates or discs are used in clutches, torque limiters, disc drives and power transmission devices. You can buy this material from the Cork Friction Material Manufacturer. This disc may consist of friction material or the plate can be lined with friction material.

Different types of friction materials:

Aramid fibers: It combine the pulling capabilities of ceramic with smooth engagement of organic materials. If it is used properly, it can outlast other friction materials by two to five times. This is lighter and tougher than the steel which provide exceptional thermal stability. You can find application of this material very common.

Ceramic material: These materials are extremely durable and well suited for heavy loaded applications. It can bear up with higher heat than other friction material. But it has a high rate of wear because of its hardness.

Organic materials: It was once made of asbestos but now these are largely made of other materials. These types of materials are used for some particular case.

Metallic friction materials: These types of materials include bronze or copper alloys, cast iron and steel. Sometimes the organic facings are made of brass and fiberglass.

Applications for friction materials:

Friction materials are used in automotive, military, manufacturing and mining application. While selecting products, buyers should identify the coefficient of friction under normal and hot conditions. The efficiency of Cork Friction Material determines the retarding force produced when two sliding surfaces are held against each other by an applied normal force.

These all are about the selection guide of friction materials. You are suggested to discuss the usage of different types of friction materials with the manufacturers to ensure safety and proper usage.